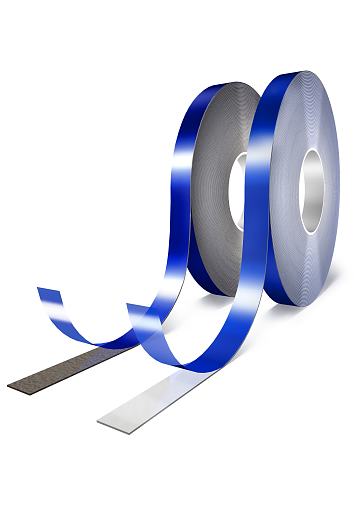

Building Tape

Reliable bonding of different substrates plays a key role in the building industry. In comparison to mechanical approaches such as welding and riveting, self-adhesive tapes are increasingly gaining in importance. Clean full-surface bonding, extreme load capacity, corrosion prevention, savings in time and costs, and good aesthetic results rank among the many advantages these high-quality adhesive tapes have to offer. In addition to the mere joining process, adhesive tapes are able to fulfill additional requirements such as vibration and shock absorption, sealing against liquids, and many more. The development of market-driven self-adhesive system solutions requires technical know-how and knowledge of industry-specific production processes. Its 75 years of experience in developing and manufacturing self-adhesive tapes have taken tesa to the top of the world market in many application areas utilizing bonding technologies. Thanks to our high innovation rate and extensive consulting expertise, we are able to solve sophisticated bonding requirements in virtually any market and industry sector. A particular challenge: constructive mounting. tesa offers a powerful portfolio of adhesive tapes, the specific properties of which take into account all the complex requirements in constructive long-term bonding of different substrates. For example, these technologically advanced products compensate for uneven surfaces and differential thermal expansions of materials, resist static and dynamic forces, and are resistant to different solvents and temperatures. The result is clean, durable bonding that can be integrated into production processes seamlessly, increasing efficiency.